What is HMI?

A Human Machine Interface (HMI) is a display device that allows users to interact with a system and exchange information. They are widely used in many industries, such as the automobiles, entertainment, electronics, medical equipment, banking, and service industries.

In industrial applications, the major functions of HMI are real-time information exchange between humans and production equipment via programmable logic controllers (PLCs), variable-frequency drives (VFDs), and meters. HMI screens display data, provide visual feedback, and execute operational commands via an input device such as a touchscreen, keyboard, or mouse.

How is HMI used in Industry 4.0?

The rise of Industry 4.0 and IIoT has transformed automation, leading to a global intelligent manufacturing revolution that shifts the paradigm from “automation” to “intelligent automation”. In the production lines of smart factories, different sensors are built into manufacturing equipment to automatically check product quality and capture device data. HMI devices aggregate data and simply process the information for a more efficient and productive system. Additionally, according to the needs of cloud applications and intelligent manufacturing, factory management and production decisions are more reliant on visualized control platforms. HMIs simplify and visualize data to make it intuitive to understand at first glance. Industry 4.0 transformation integrates IT and OT systems to share and use the management data in MES or ERP systems, and the production data in production equipment to achieve a more flexible and efficient manufacturing process. HMI devices not only perform the role of machine monitoring but they are also the hub for data processing and transmission between IT and OT systems.

Checklist to finding the right HMI solution

- Operating environment conditions

- Data processing demands

- Connectivity and data security

- Expandability and flexibility

- Operating systems and software

- Other user needs for better experiences

To fulfill data visualization needs from edge computing, choosing a right HMI can enhance factory automation and ensure productivity. Here is the checklist to review your application from different viewpoints to help you to find the correct HMI solution:

Operating environment conditions

Operating temperature

For factories built in extreme environments, or the applications exposed to wide temperature variations, HMIs with a wide operating temperature range will ensure stability. Advantech provides all kinds of industrial panel PCs and monitors with a wide temperature range -20 ~ 60°C to satisfy diverse applications and environments.

Waterproof requirements

A waterproof HMI is generally required for applications with high standards of hygiene and cleanness, such as in food and beverage manufacturing, and medical industries. The HMI waterproof level is classified by an IP Rating (Ingress Protection Rating) depending on the protection degree against foreign bodies (tools, dirt etc.) and moisture. Advantech provides an all-around waterproof HMI SPC series, including SPC-800 IP65-rated control panel, SPC-500 IP69k-rated stainless steel HMI, and SPC-200 IP66-rated classic HMI to fit diverse processing standards.

Explosion-proof requirements

HMI with explosion-proof certifications like C1D2 and ATEX are needed for hazardous fields such as in oil field drilling, pump station monitoring, chemical plants, pharmaceutical factories, oil pipeline monitoring, tank storage monitoring, and fuel station management. Advantech provides C1D2 certificated industrial panel PCs and monitors to satisfy the demands of a wide range of harsh industrial applications.

Other environmental factors

Industrial environments face conditions like dust, debris, and vibration, so an industrial grade design HMI can promise durability and a long life. For some outdoor scenarios, a HMI with sunlight-readable screen is essential so Advantech provides rugged designed industrial panel PCs (TPC, SPC, PPC series) and monitors (FPM series) to facilitate industrial automation and data visualization in diverse environmental conditions. Especially, the touch panel PC TPC-1251T/1551T supports a high brightness and low reflection screen for outdoor use.

Data processing demands

HMIs with high computing power are needed for applications processing big data or high resolution images, such as defect inspection applications used in quality control processes for the food and beverage industry, data and image calculation used in electronics manufacturing, and face recognition technology for people working in public places. Advantech provides premium industrial panel PC solutions, including the fanless touch panel PC TPC-B610 series, and the configurable panel PC PPC-600 series to realize industry 4.0 applications.

On the other hand, if the data computing requirement is lighter, a thin-client terminal HMI with lower power consumption and lower cost is recommended. Additionally, if the panel PC is to serve as a web terminal, a web-browser terminal HMI series is suggested for its embedded browser and rapid Web App development features. Advantech provides cost-effective industrial thin-client HMI solutions and web browser terminal series to fit different scenarios.

Connectivity and data security

In intelligent manufacturing, more control functions are required to process higher data complexity and larger data quantities. HMIs have to be capable of a new generation of communication protocols to ensure the stability and the immediacy of data transmission between PLCs. Furthermore, big data analysis is a valued asset when developing a digital transformation strategy, so data acquisition is key to manufacturing and factory operations. HMIs are also required to provide powerful connectivity with PCs or sensors for data transmission through Ethernet or Wi-Fi, but also to support monitoring programs and data collection systems like SCADA. Advantech provides HMI solutions such as the WOP-200K series operator panels with powerful connectivity for PLC links, and TPC-300 EHL series all-in-one panel PCs with 5G modules and 2.5 GbE speed, to accelerate and enhance data connectivity.

Since all the valuable factory information needs to be digitalized, data security is an issue to be concerned about. Choosing an industrial panel PC with TPM (Trusted Platform Module) is a way to enhance security against firmware and ransomware attacks. Advantech provides HMI solutions with Windows 11 including PPC series, Modular TPC series, and TPC-300 series, equipped with TPM 2.0 to secure confidential data by encrypting the hard drive and SSD.

Expandability and flexibility

In developing industrial IoT solutions, more and more sensors will be deployed and data processing demands will be relatively high so it’s important to invest in the expandability and flexibility of HMI solutions. Some panel PCs are equipped with extra slots to allow the upgrade of memory for future advanced data processing performance. Another option worth considering are modular panel PCs. Advantech’s Modular TPC series and Configurable PPC series provides a flexible industrial HMI solution whereby the display modules combine with box modules to offer a range of flexible platforms. They also offer forward compatibility so that operators can simply detach and replace existing modules with newer more advanced module. Modular platforms can be rapidly customized according to usage requirements and achieve easy maintenance by removing box modules for repair without unmounting the entire platform.

Operating systems and software

HMI visualization programs and interface designs are critical by directly impacting user experiences, so it is necessary to consider the programming software preferences. Advantech provides Arm-based panel PCs TPC-100 series and PPC-100 series, supporting various OS, including scalable Windows 10/11 and compact Android 10 and Linux, to facilitate development of unique applications.

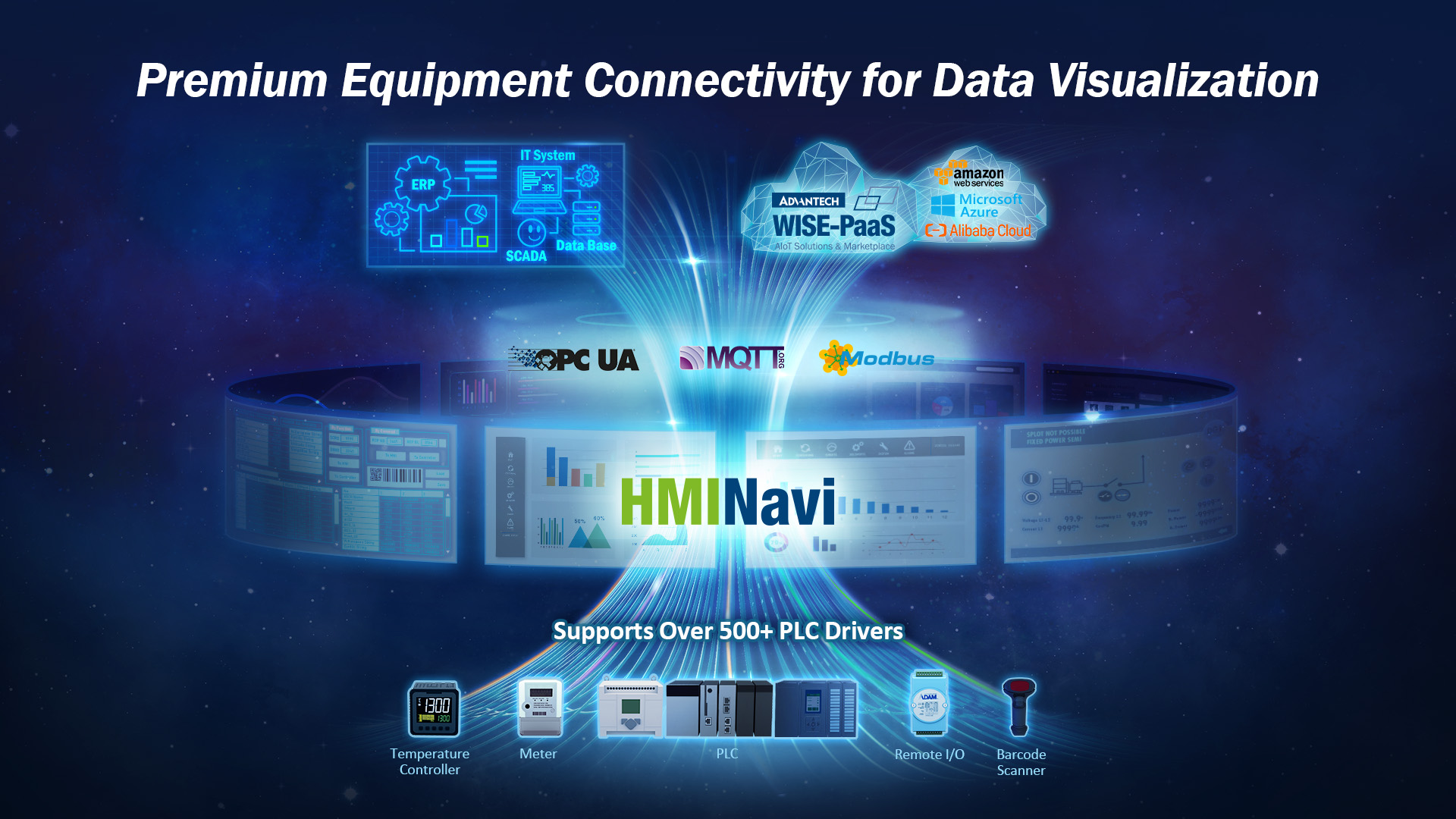

Industrial panel PC solutions with built-in apps or HMI software are also value-added choices. For example, Advantech provides a software bundle for TPC/PPC series integrated with Advantech developed HMI software. HMINavi supports easy PLC connection and data visualization, and WISE-IoTSuite/AppHub web-based solution facilitates remote device management.

It is also worth taking note of the partnership with third party software vendors to evaluate the software strengths and flexibility before choosing an HMI. Advantech co-develops with several main software vendors to provide various franchised HMI SCADA software bundle solutions with Inductive automation (Ignition), AVEVA (Wonderware), and Copadata (Zenon).

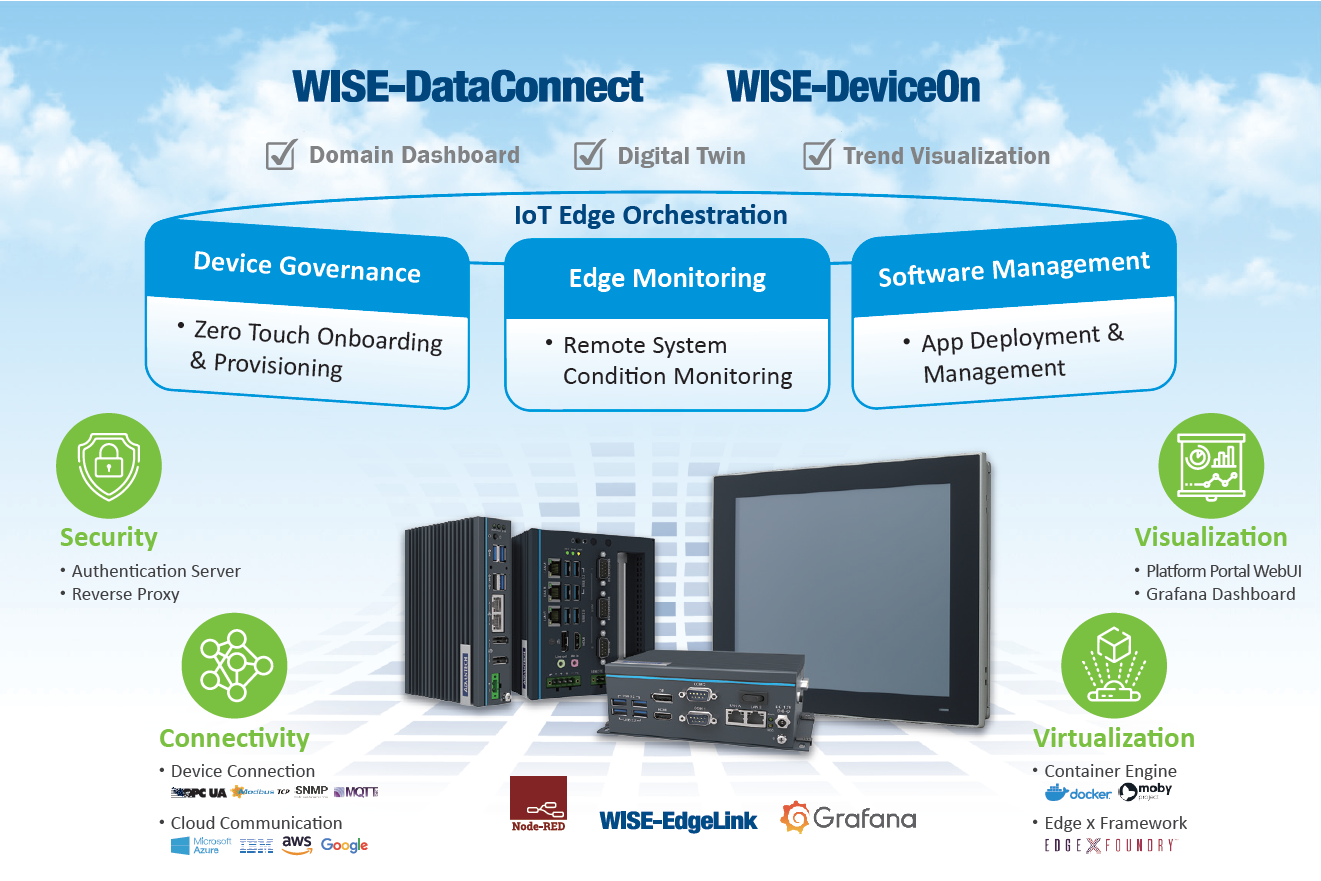

Lastly, Edge-as-a-Service (EaaS) solutions offer real-time insights and localized actions for your edge computing environments. Advantech’s Edge Intelligence solutions establish an EaaS ecosystem that combines hardware, edge services, and cloud platforms for device control, edge monitoring, and software management. In this architecture, all process and application data can be aggregated and visualized on dashboards for users. The platform portal employs container technology that can be implemented on all Advantech IT gateway devices. Moreover, the portal’s secure open-software architecture enables users/ developers to access the system via a HTML browser and allows users to integrate unique analytics and connectors.

Other user needs for better experiences

Screen size

HMI screen sizes are one of the factors to be concerned about. Usually small screen size HMIs are used for single machine control; medium sized HMI screens for facility management and connected to the MES system; and large HMI screens are perfect for remote management in control rooms. However, for smart applications, data visualization is needed, so bigger HMI screens with higher resolutions and 16:9 aspect ratios are becoming mainstream. Advantech provides various sized industrial panel PCs and monitors to support all kinds of factory applications from automation control to field data management.

Touch screen types

HMI touch screen type choices depend on the users’ requirements. If the application requires precise and accurate multi-touch capabilities such as zoom, drag, swipe, and pinch touchscreen gestures, projective capacitive (P-CAP) control touch screen types will be ideal. If the operator needs to wear gloves, then resistive touch screen (RTS) types will be preferred.

Physical buttons

HMIs that feature physical buttons are still needed for certain user demands. Since touchscreen HMIs do not provide tactile feedback like button-based HMIs, without tactile feedback, users lack keypress confirmation of touch commands, which is particularly important for those with visual impairments. Physical buttons are also helpful for eliminating issues encountered when using touchscreen HMIs: namely difficulty distinguishing graphical onscreen changes under sunlight, shifting, and unclear targets, and the need to look at a screen when performing important tasks. The existence of physical buttons allows users to quickly and accurately complete tasks. Advantech’s SPC-800 series is an industrial HMI that follows recent trends for a touchscreen interface combined with a few physical buttons. The SPC-800 accommodates user preferences for physical buttons while providing a touchscreen for more efficient operation, integrating the two interface types to optimize operational safety and ensure efficient processing.

The right HMI solution can boost manufacturing productivity and bring the industry digitalization to a higher level. Advantech, as a leading provider of industrial HMI solutions, is dedicated to the promotion of Industry 4.0 and the IIoT ecosystem.

You can buy these and other models here