Whether developing a consumer-facing kiosk or creating smart factory machinery, today’s automation designers and engineers are faced with a wide variety of hardware platforms to choose from. Different platforms are suited for varying ranges of roles, but it is crucial to understand where each family of devices plays best so the right selection can be made for each application.

Whether developing a consumer-facing kiosk or creating smart factory machinery, today’s automation designers and engineers are faced with a wide variety of hardware platforms to choose from. Different platforms are suited for varying ranges of roles, but it is crucial to understand where each family of devices plays best so the right selection can be made for each application.

Since personal computers (PCs) are so prevalent worldwide and have been for decades, it is natural for many consumers to expect PCs are directly integrated into much of the world’s automation and monitoring systems. And indeed, there is a specific industrialized version of the PC called an industrial PC (IPC) which fills this role.

Of course, there are other possible automation platform solutions such as dedicated microcontrollers, or commercially available programmable logic controllers (PLCs). Various combinations of these devices may provide the best result in some applications, but this White Paper will focus on those instances where an IPC is the best fit.

Automation controllers and computers of any type are required to accomplish a variety of tasks. They might simply monitor input signals, or may in turn have control logic activating output signals. Some may interact with users via simple operator controls like buttons and lights, while others may need to have a more advanced graphical display, much like a computer monitor. They may be called upon log data or perform advanced calculations. These systems may be standalone, but industry-wide developments concerning the Internet of Things (IoT) means it is increasingly important for any new systems to be both smart and networkable.

As with any design problem, it is essential to define goals. In this case, the main drivers for selecting automation controllers and computers typically boil down to the installation environment, the required functional performance, and the associated connectivity options. It goes without saying that cost is always a consideration. Oftentimes selecting a single device that accomplishes the greatest number of goals can result in the most cost-effective solution.

This White Paper will examine the pros and cons of various automation platform technologies to identify where an IPC offers the best fit. For many applications, this technology brings together just the right combination of characteristics to be the optimum solution for intelligent automation. Not only that, but IPCs are uniquely poised to enable the smart factory by bridging operations technology (OT) with information technology (IT) systems. We’ll start by looking at what key aspects define an industrial PC.

What Makes a PC Industrial?

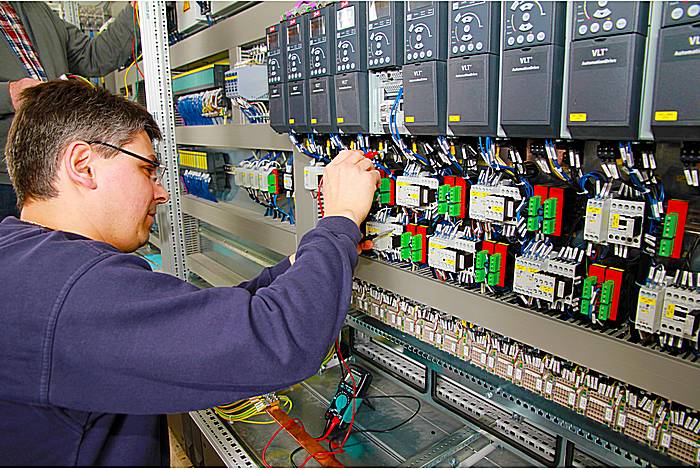

An IPC is typically box shaped and has some connectors, but that is where the resemblance to everyday consumer desktop and laptop PCs ends. IPCs are packaged for installation in control cabinets or other industrial equipment or machinery. The case is typically metal, and the assembly is ruggedized to withstand high temperature, punishing vibration, and the other characteristics of harsh environments.

Industrial PC Characteristics

- Robust packaging for harsh environments

- Can operate at high temperatures

- Fanless designs minimize mechanical failures

- Compact with many mounting options

- Based on commercial processors, memory and storage to provide a superior price-performance ratio

- Enhanced backplane connectivity

- Support for numerous fieldbus protocols

- Common commercial interconnectivity (Ethernet, Wi-Fi, USB)

- Graphical user interface via HDMI and/or VGA

Most of these IPCs are fanless and simply have cooling fins on their case. Deleting the fan makes them far more resistant to dust, and removes a significant point of mechanical failure. Therefore, reliability is outstanding. There are no consumables or periodic maintenance requirements, although if there is trouble they are modular and designed for rapid repair. In all aspects, the sustainability of these devices far exceeds their commercial counterparts, and is equal to or better than PLCs and other industrial controllers.

IPCs are not only tough; they also offer exceptional installation flexibility. Usually they are very compact and feature multiple mounting options including panel mount (bolted to equipment) and standard 19” rack mount. Another of the most popular configurations for industrial applications is DIN rail mount, a common modular mounting methodology which accepts many types of industrial automation components.

IPCs can be installed in control cabinets and other housings in a variety of ways, including DIN rail mount.

Since IPCs are derivatives of commercial-off-the-shelf PCs, configurability is one of their best characteristics. Much like their consumer brethren, these computers feature ample expansion options to add memory, data storage, connectivity options and other features. The most compact versions often use RISC architecture, while more advanced types use x86-based platforms.

The most noticeable area where IPCs diverge from consumer equipment is in backplane connectivity options. Some configurations are completely self-contained, and others may offer input/output (I/O) hardwired points on board. More capable models may have some conventional or mini PCI slots, while the most configurable systems are built on the PC/104 embedded computer form factor standard. This enables the CPU board and other peripheral boards to be tightly stacked.

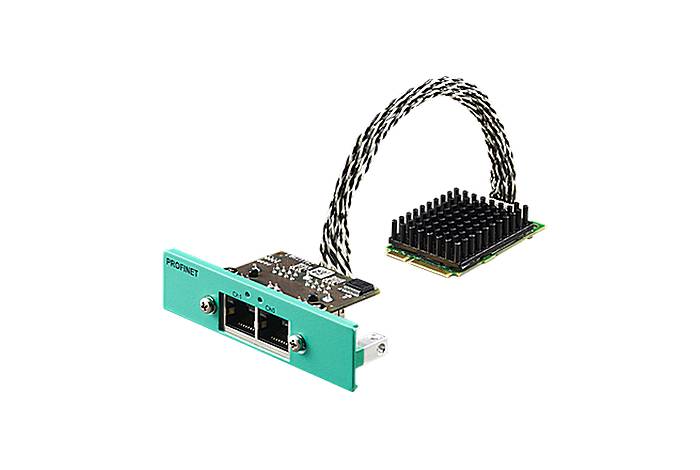

Vendor extensions may also provide connectivity for a variety of fieldbus protocols, more advanced I/O, or other smart sensors. These types of connections are extremely relevant for industrial and process machinery applications. For example, Advantech’s iDoor technology provides a variety of connectivity options.

|

|

|

Advantech's iDoor technology provides a variety of different connectivity options for their IPCs and does so in a modular fashion.

Other network interfaces align with common commercial capabilities. IPCs include USB ports for connecting to typical peripherals such as input devices and printers. Local area networks can be accessed via Wi-Fi or hardwired Ethernet. Standard memory card slots provide a convenient method of loading and backing up data.

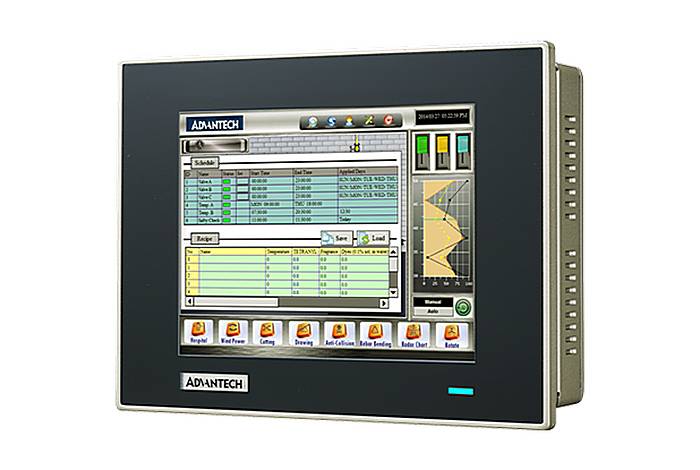

Perhaps the most significant ability which differentiates IPCs from microcontrollers or PLCs is the inclusion of HDMI and/or VGA ports, so that a display can be directly operated by the hardware. This increases the likelihood that the device can act as an all-in-one solution. Many IPCs are packaged with integral displays, creating a very compact and cost-effective platform.

|

|

A big advantage of IPCs is availability of units with integral displays - saving money, space, and integration effort.

As a full-fledged networkable computer, an IPC is natively positioned to interface with IT-based systems.

This means that an IPC is the natural fit to bridge operational equipment and systems with higher level corporate databases, an enterprise resource planning (ERP) system, a manufacturing execution system (MES), and an asset management system (AMS). These systems can be on premises and connected via hardwired Ethernet, or can be reached over the Internet via cloud services.

At a much more granular level, IoT devices such as motor controllers may be aggregated by one or more IPCs in order to provide an organized method of Internet connectivity and remote access to these smart devices.

If IPCs offer so many advantages, then what do some competing options bring to the table?

Other Options

Other automation computing platforms exist and have their places. As we will see, selecting from these alternatives may not be a simple either/or situation, and in fact a combination may be provide the best solution. Dedicated embedded microcontrollers and PLCs are two of the most prevalent options outside of IPCs for use as automation platforms.

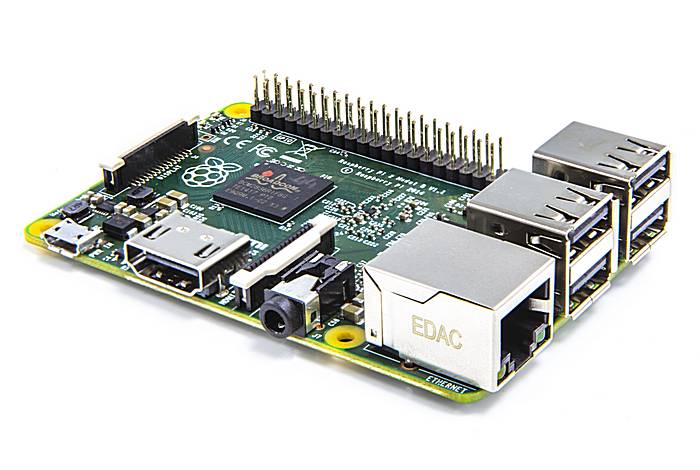

Dedicated embedded microcontrollers are especially economical for products with very high annual sales, on the order of tens of thousands of units. This is because they are developed specifically for the application, and have just enough functionality so no expense is wasted on extra features.

But there are many downsides. Substantial engineering and design effort is required on the part of the user to develop the application-specific microcontroller and integrate it into the end product. A limited number of specific configurations are usually available, and the hardware will likely need to be protected from the operating environment. More advanced industry-specific capabilities, such as fieldbus, are less likely to be available.

|

|

Microcontrollers are inexpensive but considerable time and effort is required to create housing suitable for industrial applications.

These devices are more difficult to program because they don’t benefit from the user-friendliness of mass-marketed devices. With no commercial vendor to rely on, users must provide their own product support for these microcontrollers, adding to the total cost of ownership.

On the other hand, PLCs represent a much more packaged and generic option with excellent performance for real-time control of discrete and certain analog processes. They can be thought of as microcontrollers prefabricated into a box, with additional enhancements. They cost more than microcontrollers but still benefit from economies of scale.

PLCs excel at real-time control of simple to moderately complex systems but can't match the performance and features of IPCs.

In recent years, PLCs have been the go-to commercially available product when a hardened system was needed. In fact, ControlEng.com says (Reference 1) PLCs may be considered “a mature technology with little room for improvement as they've been around for nearly 50 years. But like their close counterparts in the world of consumer electronics, significant improvements continue with no end in sight, promising faster, smaller, and lower cost solutions.”

Yet PLCs have some serious limitations, particularly in certain applications. Data handling and memory capabilities may not meet requirements, and more advanced control strategies such as coordinated motion and vision are very hard to implement. PLCs are more likely than microcontrollers to offer fieldbus connectivity, but may not have the desired networking protocols. PLCs may still require a PC platform to fully achieve IoT and IT connectivity. And like microcontrollers, PLCs are not well understood by IT personnel, complicating integration into higher level computing systems.

Another significant downfall of microcontroller and PLC solutions compared with IPCs it their lack of native operator interface capabilities. Microcontrollers commonly require separate hardware and software to provide any kind of user interface. PLCs usually offer compatible hardware based operator interface terminals, and PC-based software platforms can act as the human-machine interface (HMI). By contrast, IPCs are natively able to operate with user input devices and displays, and can be purchased with integral displays in screen sizes up to 21.5” or more.

Sometimes the right decision is to use an IPC in conjunction with a microcontroller or PLC. In this configuration, the microcontroller or PLC would handle direct I/O monitoring and control, while all higher level functionality, operator interface, and network connectivity performed by the IPC. From a purely technical standpoint, using an IPC to provide HMI capabilities and bridge PLC or microcontroller functionality to a higher level is very attractive. Of course, adding platforms into a design adds cost, requires much more space in the control cabinet, and complicates design and support.

This is why in certain situations it is desirable to look to an IPC as the all-in-one automation solution.

IPCs Overcome Microcontroller and PLC Shortcomings

IPCs can certainly support mundane I/O handling and communications tasks, but where they really excel is as an all-in-one solution any time an automation application requires more advanced capabilities and performance.

Industrial PC Benefits

- Versatile packaging lets them go anywhere

- Hardware performance is completely scalable

- Can host a wide range of operating systems

- Can run advanced control and other software

- Can perform real-time control

- Excel as graphical user interfaces

- Ideal bridge from operations technology (OT) to information technology (IT)

- Readily used by both OT and IT personnel

As has already been pointed out, IPCs feature many physical characteristics that make them right at home in any piece of industrial equipment. More importantly, users can buy just as much hardware performance as they need. A wide range of commercially developed processors is available to meet any need. Memory and storage options are inexpensive commodities. IPC platforms are inherently scalable for any application, and since they are built from the latest commercial components, they offer superior price/performance ratios compared with other options, making them a good fit for the most demanding applications.

When it comes to connectivity and networking, IPCs offer additional options compared to any other automation platform. Not only that, but they can provide industrial operations-type connectivity (such as fieldbus and serial links) just as well as commercial IT-type connectivity (such as Wi-Fi and wired Ethernet and HDMI).

From a software standpoint, IPCs are available to run various operating systems such as Linux, Windows Embedded, and the latest version of Windows. These operating systems enable users to utilize any necessary commercially available software, or develop on the platform of their choice.

One example of where IPCs shine is when complicated algorithms must be applied to achieve advanced process control (APC). These algorithms may require local data storage and averaging, and computational math tasks, tasks best suited for an IPC. Motion control and vision applications also typically require a PC platform to execute their software and provide higher level functionality.

In many cases, if the designer must already include a PC for communications or operator interface purposes, the best solution is to consolidate all operational tasks into the IPC. The result can be a simplified system with reductions in material and engineering costs. Whether an IPC is implemented as an all-in-one solution or in conjunction with other controllers, it brings intelligence to equipment and serves as the bridge to supervisory systems and other higher level computing platforms. Personnel familiar with the operational equipment can natively configure PC-based control and operator interface in one device.

On the other hand, personnel familiar only with commercial IT infrastructure will be much more familiar with the PC and Ethernet ecosystems, and can use other enabling technologies such as remote management. IPCs fit the bill for many markets, including those described below.

IPC Markets

Microcontrollers, PLCs, and IPCs are applied across a spectrum of markets and applications. It is helpful to look at some typical scenarios.

Machinery and process control equipment on the factory floor always requires some form of automation platform. Mass-produced equipment such as simple shop machinery, discrete part handling units, or test and inspection equipment may tend to use microcontrollers or low-end PLCs, since the production quantities can justify the additional up front development expense. Lower volume, custom or complex systems would tend toward using high-end PLCs and/or IPCs, since these more commercialized offerings can help the manufacturer build their product faster while saving money in engineering and design.

An important reason for including an IPC with any form of manufacturing equipment is the industry drive to “smart factories”, also known as “Industry 4.0”. This concept calls for all manufacturing physical systems to be modular and easily capable of integrating with each other and higher level systems for control and monitoring purposes. Microcontrollers, and to a greater extent PLCs, have some limited capabilities in this area, but IPCs are the ultimate method for enabling smart factories.

Another class of products is consumer-facing systems, such as retail product kiosks or medical equipment. These types of systems are far more likely to use PCs of some sort rather than other options. Again connectivity to Ethernet and other peer or higher level systems is a key need. The other significant differentiator is the increasingly common requirement for a graphical user interface, which IPCs natively excel at providing, either via an external monitor or integrated into a single IPC/monitor housing.

Traditional methods of providing an operator interface for an automation system included buttons, knobs, thumbwheels and numerical readouts. Unfortunately, this practice is very limiting and inflexible once implemented, not to mention expensive from a design and material cost standpoint. Providing a rich user interface experience for automation systems is where the full power of IPCs can be brought to bear.

Today, users are coming to expect even rugged factory equipment or specialized consumer devices to offer the same friendly user interface experience provided by their phones, tablets, computers and televisions. As EDN-Europe.com observes (Reference 2), “The user interfaces of today’s smartphones are setting the standards for design in other spheres such as industrial equipment.” An IPC can readily be scaled to provide the necessary performance, and supplied with the proper operating system and software to provide the advanced user interface required for many commercial and industrial applications.

Application Example

In some industries, an equipment manufacturer may choose IPCs to act as a common consolidating platform for a variety of automated equipment offerings. Consider a manufacturer who designs and produces a wide variety of discrete parts handling and assembly machines. Some mainstream designs may be delivered with dedicated microcontrollers; while more customized efforts would use PLCs.

By offering an IPC in conjunction with all of their machines, several goals can be accomplished. First of all, the IPC is readily adaptable to interface to and work with either underlying platform. This frees the vendor to choose exactly the best control option in any case. In fact, for some applications it is likely that the IPC itself can be the control platform.

Secondly, the IPC provides a typical networking interface as well as a consistent user interface. The vendor thus minimizes redevelopment costs for each new type of machinery by reusing hardware and software methods, while providing a common “look and feel”. Users appreciate the ability to easily integrate new machines without having to reinvent the wheel each time. Also, a consistent user interface makes it easier for end users to initially train their employees, and even to cross-train them on more systems.

Integrating IPCs into automation systems is a powerful way to bring intelligence to any operation.

Conclusion and Outlook

More than ever, equipment and machine designers can choose from a wide spectrum of automation technology options. Meanwhile, end users are becoming more sophisticated and now expect equipment to feature advanced communication capabilities and user interfaces.

IPCs are uniquely positioned to offer just the right consolidated combination of robust packaging, hardware performance, software potential, control capabilities, graphical user interface and cost effectiveness. For many applications, either integrating an IPC with other devices or making it the foundation automation platform is the best choice.

One option is to integrate various controllers, operator interfaces and other devices to deliver the necessary results. In this case each component is mission-specific, and the IPC is chosen to provide network interconnectivity and the graphical user interface. This approach introduces some complexity and expense, but offers extensive flexibility.

In many cases, the IPC has more than enough functionality to be the all-in-one automation platform solution. Equipment manufacturers can leverage the full range of IPC capability to provide a full range of real-time control capabilities, extensive data handling and manipulation, a rich user interface and powerful connectivity.

Versatile IPCs are often the premier choice for bringing intelligence to automated equipment. They represent the optimal solution for bridging the worlds of operational equipment and information technology to enable the smart factory.