Introduction

The automobile industry is technology- and capital-intensive and full of high-precision, complex processes. Vehicles are made up of thousands of components, and even missing one screw can impact a car’s safety and reliability. Benefiting from concepts like Industry 4.0 and IIoT, smart factories are filled with machines and other equipment that facilitate intercommunication and data collection. Real-time monitoring and process controls make it possible to oversee each part of the production process. In the manufacturing world, the Human Machine Interface (HMI) is the communications bridge between humans and machines, so HMI systems are equipped with touchscreen panel PCs, offering a control screen interface and visual SOP operation procedures for production monitoring, system diagnostics, and data collection. This allows machine operators to accurately complete processes according to on-screen guidance and reminders.

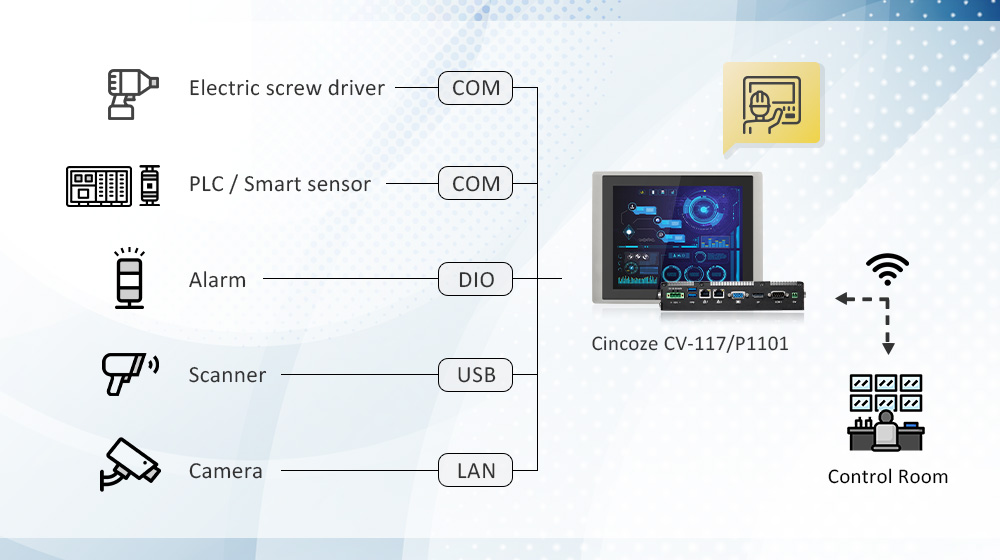

A well-known car manufacturer in Taiwan uses Cincoze’s industrial panel PC to implement an HMI in its production line. The factory’s tally system sends engines and transmission systems to the assembly line, where an operator uses a torque wrench to secure screws and measure the torque. These operating procedures, including the location of the screw lock, quantity, and torque data, must be shown on the panel PC. The control center also digitally collects data to track the production process.

Customer Requirement

Large and Durable Touchscreen Display

The factory assembly line requires a 17” touchscreen panel PC. Operators are guided to complete tasks clearly and intuitively thanks to the large screen. At the same time, a panel PC installed next to the assembly line clearly shows the collected data for instant transmission. The panel PC must be robust and durable enough to survive the challenging assembly site conditions.

Monitor and Record Data

As relevant information is displayed on the panel PC, the integration of smart sensors into the torque wrench lets operators see whether the correct number of screws are locked into position and if the torque is accurate. If one screw is missing, or if the torque is incorrect, the warning light will turn on, and operators will be unable to proceed. Data is simultaneously sent back to the control center, which helps to monitor the production line and manage traceability.

Long-Term Supply

Car production is a labor-intensive industry, with factories containing many machines and production lines. Shutdowns or maintenance of production equipment can cause huge losses for factories. As a result, factory operators place great value on long-term parts availability and high-quality after-sales service.

Why Cincoze?

Comprehensive, Robust Panel PCs

Cincoze’s range of Display Computing - CRYSTAL panel PCs come with a comprehensive range of options, including 8” to 24” screens and 4:3 and 16:9 display ratios. Touch methods include an ultra-sensitive multi-point projective capacitive touchscreen (P-CAP) or a single-point resistive touchscreen, and are equipped with Intel® Atom®, Pentium®, or Core™ high-performance processors. At the same time, they facilitate HMI applications in harsh industrial conditions. The display has a tough die-cast aluminum alloy frame, the touchscreen surface hardness reaches 7H (only P-CAP models), and the front frame has an IP65 water- and dust-proof rating. In addition, the fanless computer design supports 9–48V wide voltage power input, and -20°C to 70°C wide temperature operation to ensure durability and reliability, even in challenging industrial environments.

Rich I/O and Network Connectivity

The CV-117/P1101 features 2x GbE LAN, 4x USB 3.2, 4x RS-232/422/485, and 8x Isolated Digital I/O (4 in/4 out), allowing the panel PC to connect to sensors, motion control, and other industrial machinery. Data can also be uploaded to remote systems, with a 4G/LTE wireless communication module connected to the built-in Mini PCle slot meeting wireless connectivity requirements. The CV-117/P1101 also supports Cincoze’s exclusive CFM technology, which can be used to add PoE and ignition sensing functions.

Long-Term Product Availability and CDS Technology

Cincoze’s panel PCs use only reliable industrial-grade components and include 15 years of support. Furthermore, Cincoze’s patented CDS technology lets users extend the product lifespan by replacing components when necessary. The modular design enables the quick replacement of the display or computer modules, thus reducing maintenance downtime. Users can also enjoy the flexibility of upgrading the screen options or computing platforms of their existing systems.