Upgrade for Water Pumping Station SCADA System in UAE University

Project Introduction

The scope of this project was to upgrade the control and SCADA system of the portable water pumping station at UAE University. This facility discharges water through the water distribution system to various locations inside the university campus. The SCADA system monitors and controls the pumping station through a dedicated Programmable Logic Controller (PLC) setup and I/O modules that communicate with field devices and equipment.

ETEK FZE, Advantech Solution Partner in the region was awarded this project, which included the supply, testing, and commissioning of all systems using Advantech products and solutions. ETEK is a UAE based technology and integrated solutions provider that delivers a full range of products, services, and support to clients within the GCC and Levant region. They provide industrial applications, automation, and business application solutions that focuses on water, utilities, and IFMS, MES/MIS industrial automation solutions and infrastructure markets.

System Requirements

The station pumps are designed to draw water from the reservoir within the UAE University pumping station, and pump the water into the water distribution system to satisfy the water demand of various locations inside the University Campus. A system was required that could process the pumping water from the reservoir within the pumping station plant out into the distribution system. The AADC water main pipeline serves as a source of the water. The pressure in the water network was used as the primary control parameter for determining when the PLC should start and stop the pumps.

System Description

The pump station consists of five fixed speed pumps, which are assigned duties based upon their respective start and stop pressure setpoints. The water reservoir receives raw water from the main pipeline. Water is pumped from this reservoir out into the distribution system. The discharge flowrate and pressure are used in the operation of the pumps. The pumping station consists of the following control/equipment: 5 x pumps, 2 x jockey pumps, 16 x motorized operated valves, 2 x level transmitters, 2 x flow meters (Inlet and Outlet), and 1 x pressure transmitter. The tank farm area consists of six tanks located in three remote areas inside the university campus. The tank levels and inlet valves to the tanks are controlled by the locally installed RTU’s.

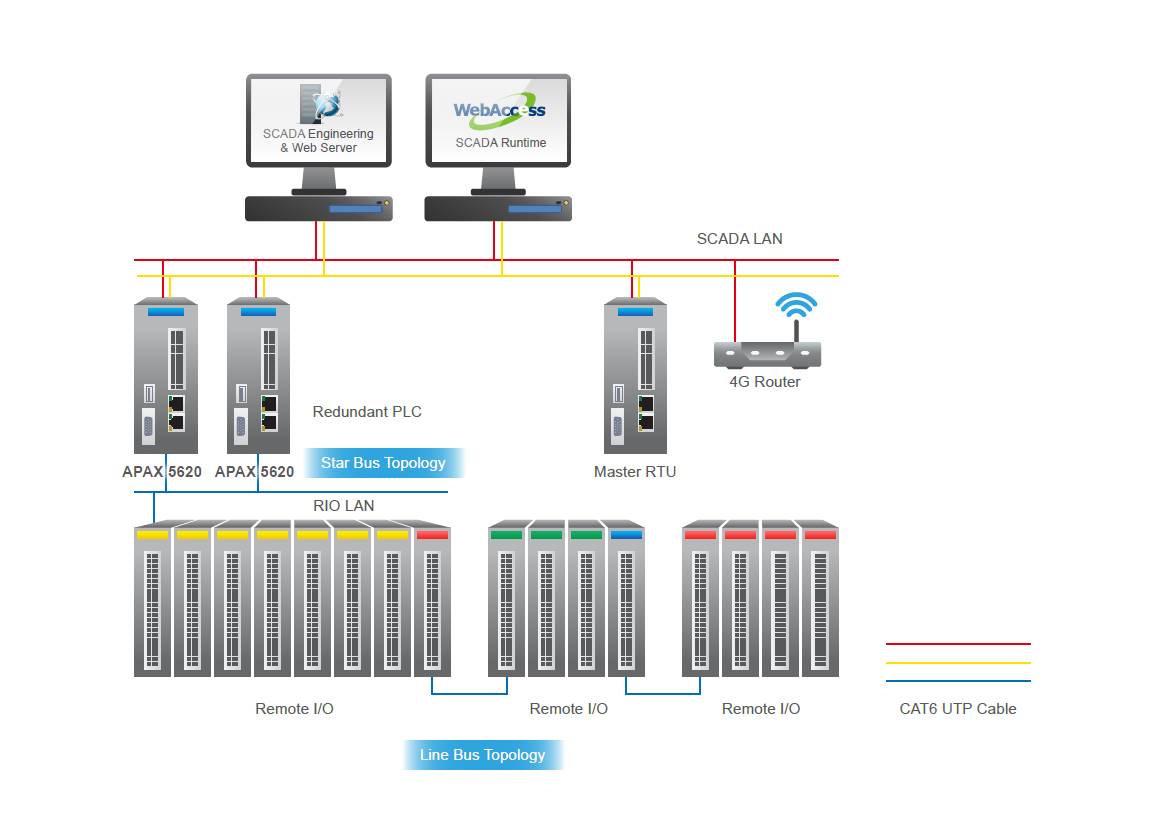

In the old system, two redundant series 90-70 PLCs from GE (Hot – Standby) communicated with Versamax remote I/O over a redundant genius bus. The old PLC system monitored reservoir levels, tanks levels, flow, and pressure. In addition, there was another PLC master series 90-30 that connect to two remote RTUs on the site. The existing legacy GE system PLC and SCADA system were completely replaced with Advantech SCADA/PLC systems.

The following Advantech products were proposed and installed in the pumping station: An APAX-5620KW Intel XScale PXA270 as PLC with APAX-5017 12-Ch AI, APAX-5028-AE 8-Ch AO, APAX-5040-AE 24-Ch DI, and APAX-5046-AE 24-Ch DO. AI modules were used to manage the pump and collect information from it. The data was then sent wirelessly to the control center using Advantech a SmartFLEX SR3030 router. To manage this data feed in real time and configure the pumping stations from anywhere, an Advantech WebAccess/SCADA System was installed on an Advantech IPC-7130L workstation at the central control room.

There are many advantages of WebAccess over the existing SCADA systems like having a centralized system that is able to view, control and configure any of the pumps remotely over the Intranet or Internet from any web-browser and mobile device. Maintenance costs are significantly reduced by providing an unlimited number of clients, so there is no restriction on the amount of users or devices that can access the system, making it easy for new staff to access the system without the need for additional purchases.

Conclusion

By using Advantech’s cost effective solution, ETEK was able to provide a system that was easy to develop and engineer at a much more efficient level than in the previous system. With considerably less operating and maintenance costs, this total solution enables engineers to access all of the system’s pumps from university central control room. Not only is Advantech’s hardware easy to install and maintain, but with Advantech’s WebAccess SCADA solution it can be fully managed from any location. With hundreds of pre-installed drivers available for third party devices, the ability for WebAccess to manage legacy systems is unparalleled.