Industrial TV Monitoring System for the Coal Chemical Processing Project

Background

The Shaanxi Coal and Chemical Industry Group has built the world’s largest coal chemical project of its type, in which processes such as the pyrolysis and hydrogenation of raw coal are used to produce end products including high value-added materials, battery electrolytes, biodegradable plastics, and special oil products. The plant required a television surveillance system for monitoring production and safety. This system would require installing video cameras at production units, shared spaces, and auxiliary buildings. The video signal would then be uploaded via digital signals through industrial-grade gigabit optical converters and a proprietary video LAN to a central control room, where it would be viewed and stored.

System Requirements

- The main areas of surveillance included key production areas, entrances and exits, the perimeter of the plant, primary thoroughfares, and other important locations.

- A wide variety of surveillance equipment was used at the plant, including fixed bullet network cameras, high-speed dome network cameras, PTZ network cameras, and smart warning cameras. Thus, the system had to be able to accept and transmit signals from different types of cameras. Furthermore, the signals would be transmitted through Gigabit Ethernet, which would offer the best stability and reliability.

- The large size of the plant and the substantial number of surveilled locations necessitated an IP-based digital surveillance solution, with each video signal having its own IP address, as this would offer the best flexibility and performance after taking into account the cost, maintenance requirements, and availability of spare parts. In addition, the long distances between each location was a challenge for connecting the cameras to the central control room.

Project Implementation

- IMC-370I-SFP: Mini Hardened Media Converter, 1000Mbps, SFP

- EKI-2725FI: 4GE+1G SFP Unmanaged Ethernet Switch

- IMC-318I: Hardened Centralized Powered Media Converter Chassis, Rackmount, 18-slot Chassis

System Description

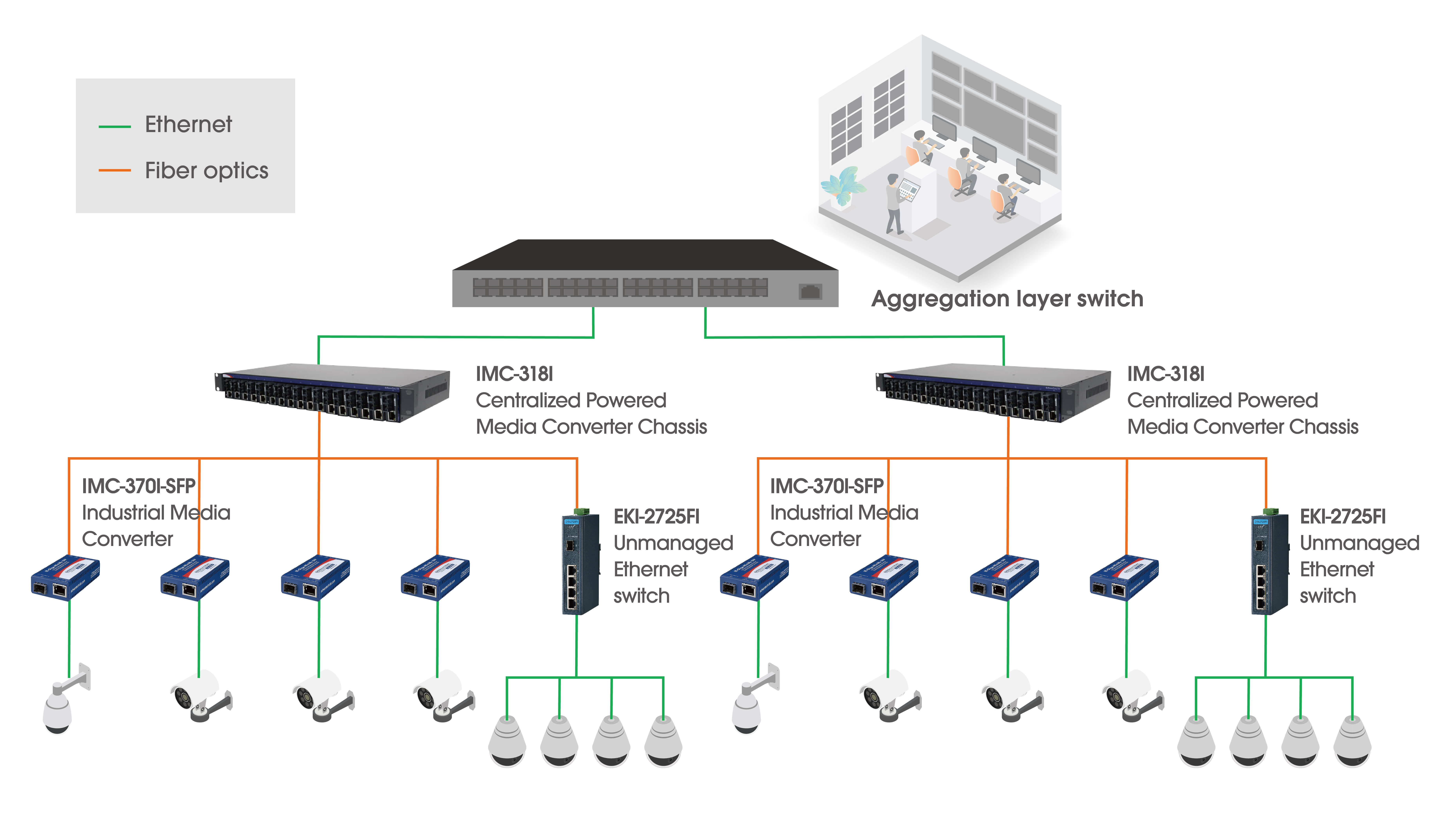

The solution adopted a star network structure with three layers: an access layer, convergence layer, and a core layer—which would each be linked with Ethernet connections. End terminals with cameras were set up at locations where surveillance and operations took place, which would each be connected to a dedicated security monitoring network. The inputs from the high-resolution network cameras in the access layer were received by Advantech IMC-370I-SFP-A mini hardened media converters, which were installed in the camera housing chassis with Advantech EKI-2725FI-AE unmanaged Ethernet switches. The signals would converge on the Advantech IMC-318I-US hardened centralized powered media converter chassis in the control room, which would also provide power to converters. This formed a dedicated monitoring LAN for the video surveillance system, adopting a system architecture based on IP applications with full switching and direct data storage. Furthermore, the video data from each surveilled area would be connected to the comprehensive management and storage platform in the control room, thus enabling the management of all system devices from a central location and ensuring the safety of the plant’s working environment regardless of the long distances between each site. The multiple advantages of this design:

- The control room provides a centralized location from which the surveillance system can be monitored and controlled, thereby allowing for a rapid response when necessary. Furthermore, video data could be stored in a centralized location that is easy to oversee.

- Fiber optics can transmit higher bandwidth and longer distance, which is a perfect solution for the plant surveillance system, which installed a lot of cameras for comprehensive monitoring.

- IP-based Gigabit Ethernet connections offer better reliability and data transmission capabilities.

The EKI-2725FI series of Ethernet switches can handle input from multiple cameras, which allows the system to be expanded if necessary in the future.

System Diagram

Conclusion

This system is an example of a television surveillance and monitoring system implemented in an industrial setting for safety and security purposes. By installing network cameras to oversee key areas, then transmitting the data from the terminal cameras to a central control room through a dedicated LAN composed of optical converters, Gigabit Ethernet connections, Ethernet switches, and media converter chassis, the customer had a monitoring system that is robust, easy to control, and expandable to ensure the safety of both people and property.

Why Advantech

- Advantech offers a wide range of media converter products, one-to-one optical converters, multi-to-one optical converters, centralized powered media converter chassis, and optional small form pluggable (SFP) modules to provide customers with full gigabit network transmission solutions. Furthermore, all optical converter products are robust and suitable for industrial and outdoor settings, capable of operating at temperatures from -40°C to 75°C.

- The IMC-370 series of media converters are small and compact and can be installed directly in the housing of cameras.

- The IMC-318 series of centralized powered media converter chassis provide a unified power supply for optical conversion modules, supporting up to 18 slots. Furthermore, the design of the IMC-318 facilitates neat cable management.

- The EKI-2725FI series of Ethernet switches can handle input from multiple cameras, thereby allowing greater expandability.