Product review of ADAM-3600

ADAM-3600 is a universal device for remote control of industrial facilities, data collection, monitoring and process automation.

At the same time, it can act as a communication device with an object, a data acquisition and transmission device, and a programmable logic controller (PLC). Has expansion modules for I / O ports, as well as modules for wireless interfaces Wi-Fi, 4G / 3G / GPRS, ZigBee, GPS.

The device runs on the RealTime Linux operating system and the Cortex A8 processor. Supports open industry protocols ModBus, DNP3, MQTT, HTTP REST API. It can be integrated into any SCADA system. It also supports integration into IoT cloud systems such as Microsoft Azure IoT Hub, Amazon AWS IoT, and others.

In the article we will analyze the main functions of the device and get acquainted with the scenarios of using the controller in the construction of industrial control systems.

Specifications:

- Processor: Cortex A8 600MHz

- RAM: DDR3L 256MB

- USB 2.0 host: 1

- VGA: 1

- Serial Ports: 1x RS232 / 485, 2x RS485

- Ethernet Ports: 2

- Digital Inputs: 8 (expandable to 40)

- Digital outputs: 4 (expandable to 20)

- Analog Inputs: 8 (expandable to 24)

- Analog Outputs: 0 (expands to 16)

- mPCIe-слоты: 1 x Half-Size, 1 x Full-Size

- I / O expansion slots: 4

- Wireless interfaces: Wi-Fi, 3G, 4G GPRS, ZigBee (optional)

- Self-powered Real Time Clock: Yes

- SD card: yes

- Temperature Ranges: -40 to 70 ° C

- Power Supply: 8 to 30V

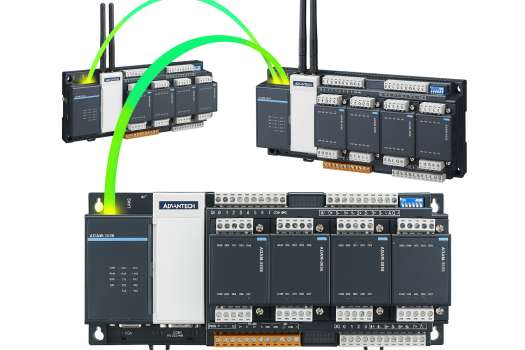

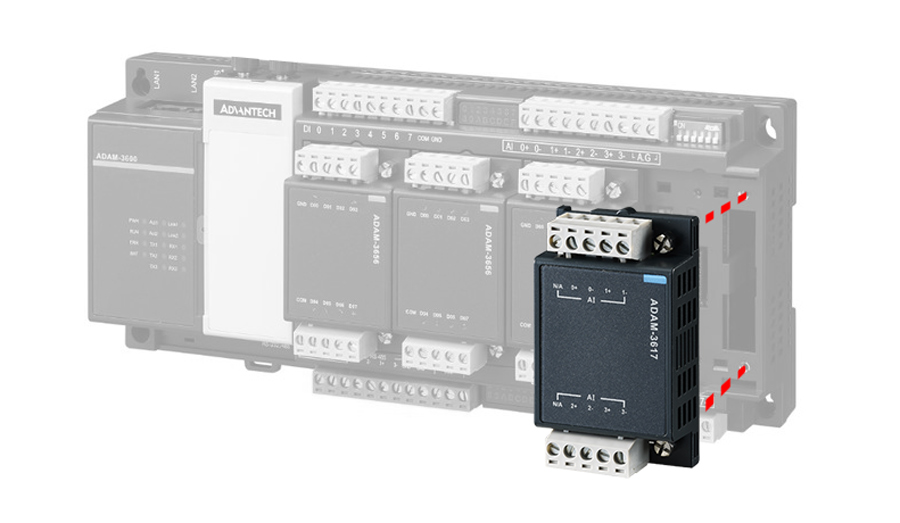

Port expansion modules

The number of I / O pins can expand depending on the needs of the customer. Up to 4 interface expansion modules can be installed in the ADAM-3600 controller. There are 6 types of modules: digital inputs / outputs, analog inputs / outputs, inputs for thermocouple (T.C.) and resistor sensors (RTD).

Interface expansion modules installed on the front panel

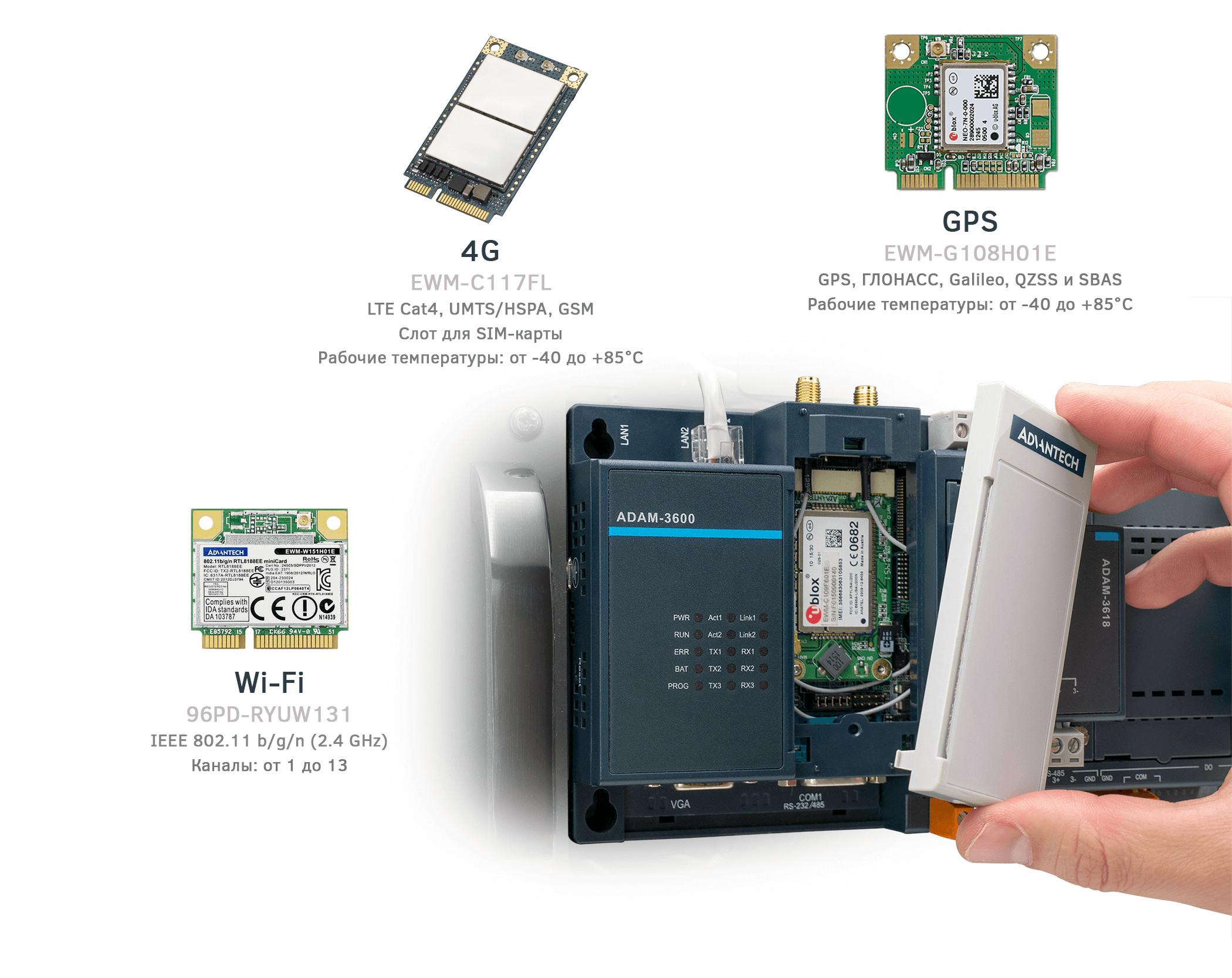

Wireless interfaces

Thanks to the presence of mPCIe ports, the Zigbee, Wi-Fi, 3G / 4G / GPRS, GPS wireless interfaces can be easily added to the controller. Two mPCIe modules can be installed at the same time: one full-size and one half-size. Both branded Advantech modules, as well as third-party ones, manufactured by Huawei, Quectel and others, are supported.

Depending on the type of antenna, the appropriate connectors are installed: SMA or RP-SMA. The antenna outputs are connected to the boards through a standard U.FL connector.

Network functions

The ADAM-3600 has two independent Ethernet ports on board that can be used in switch mode, or split into WAN and LAN. This is convenient for connecting several controllers in series in a daisy-chain topology, and does not require the installation of additional switches on lines longer than 100 meters.

Two LAN ports allow devices to be connected in series

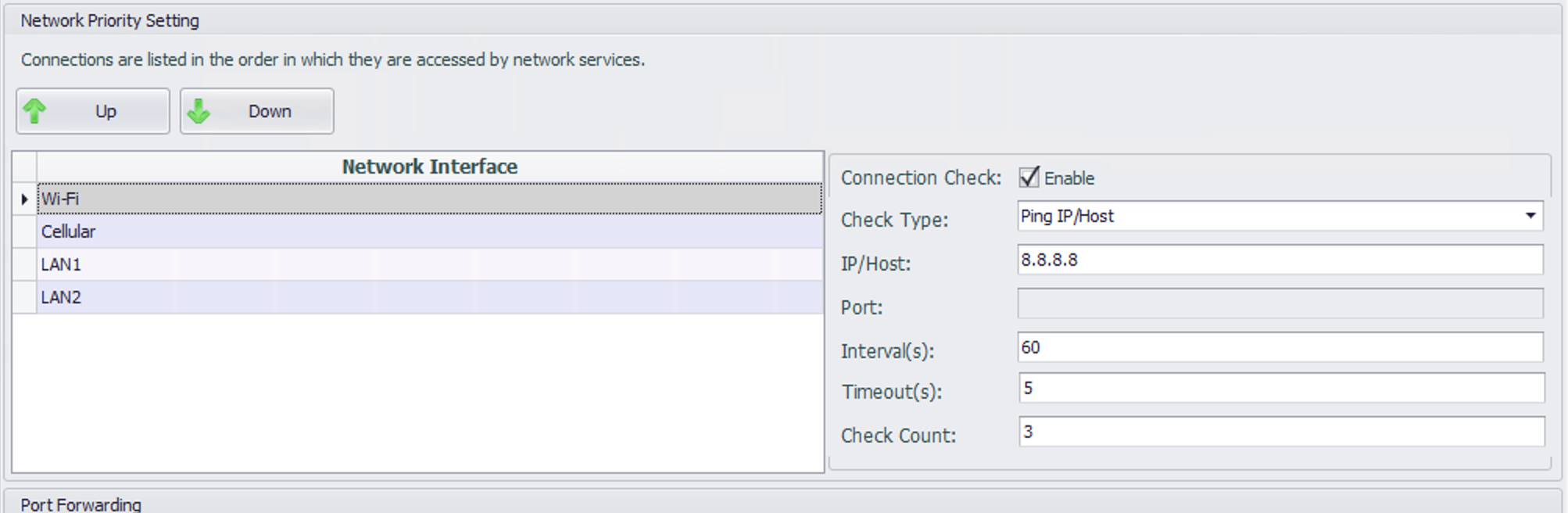

Failover Mode and Multi WAN

For remote critical infrastructure facilities, loss of communication can cost significant losses. Therefore, to increase the reliability of communication, the ADAM-3600 has a channel redundancy function in failover mode. If communication is lost on the main channel, the controller will automatically switch to the backup, for example, from wired Internet to 3G. The priority of the channels and the address for checking the connection are configured in EdgeLink Studio.

Channel priorities and Failover mode setting

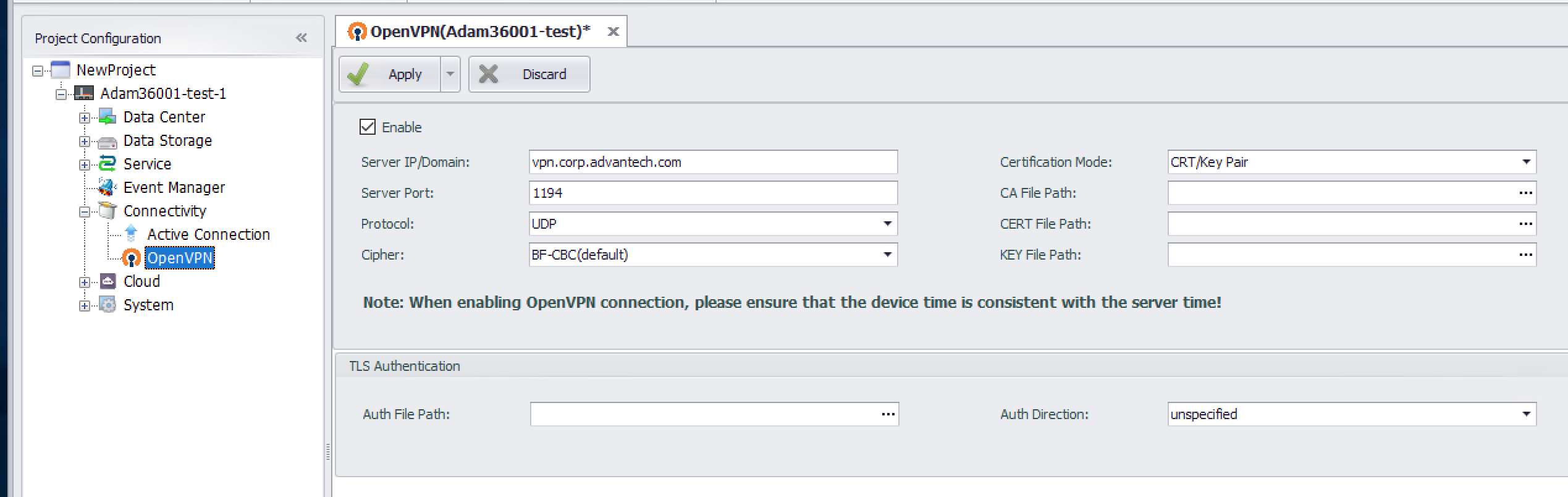

VPN support

Support for the current version of OpenVPN 2.4 allows you to integrate devices into the virtual network of the enterprise. UDP and TCP tunnels, certificate authentication, and advanced encryption algorithms such as AES-256-CBC are available.

Configure OpenVPN Tunnel in EdgeLink Studio

Device Hardware ID

A quick initial configuration can be set using the DIP switch on the front panel. NodeID sets the device identifier and starting IP address. This allows you to install a large number of devices without preliminary configuration, and further configuration is performed remotely over the network.

Device ID can be set using jumpers

Operating modes

The main feature of the ADAM-3600 controller is its versatility. It can be both a data acquisition device (recording and transmitting telemetry), and a communication device with an object (transmitting control commands from a control center), and a programmable controller (automation control).

Each use case has its own development environment.

Data Acquisition Unit and Remote Terminal

ADAM-3600 can operate as a classic data acquisition and transmission device (DTD). One of the additional features is data processing before sending. For example, the standard deviation or readings of the sensors of raw values of current or resistance can be calculated, and the finished data is converted into the appropriate format for various databases, for example, MS SQL Server. Saving data can be performed on the SD-card, in the case when the Internet connection is not available. After the connection is restored, the data will be transferred to the server without loss.

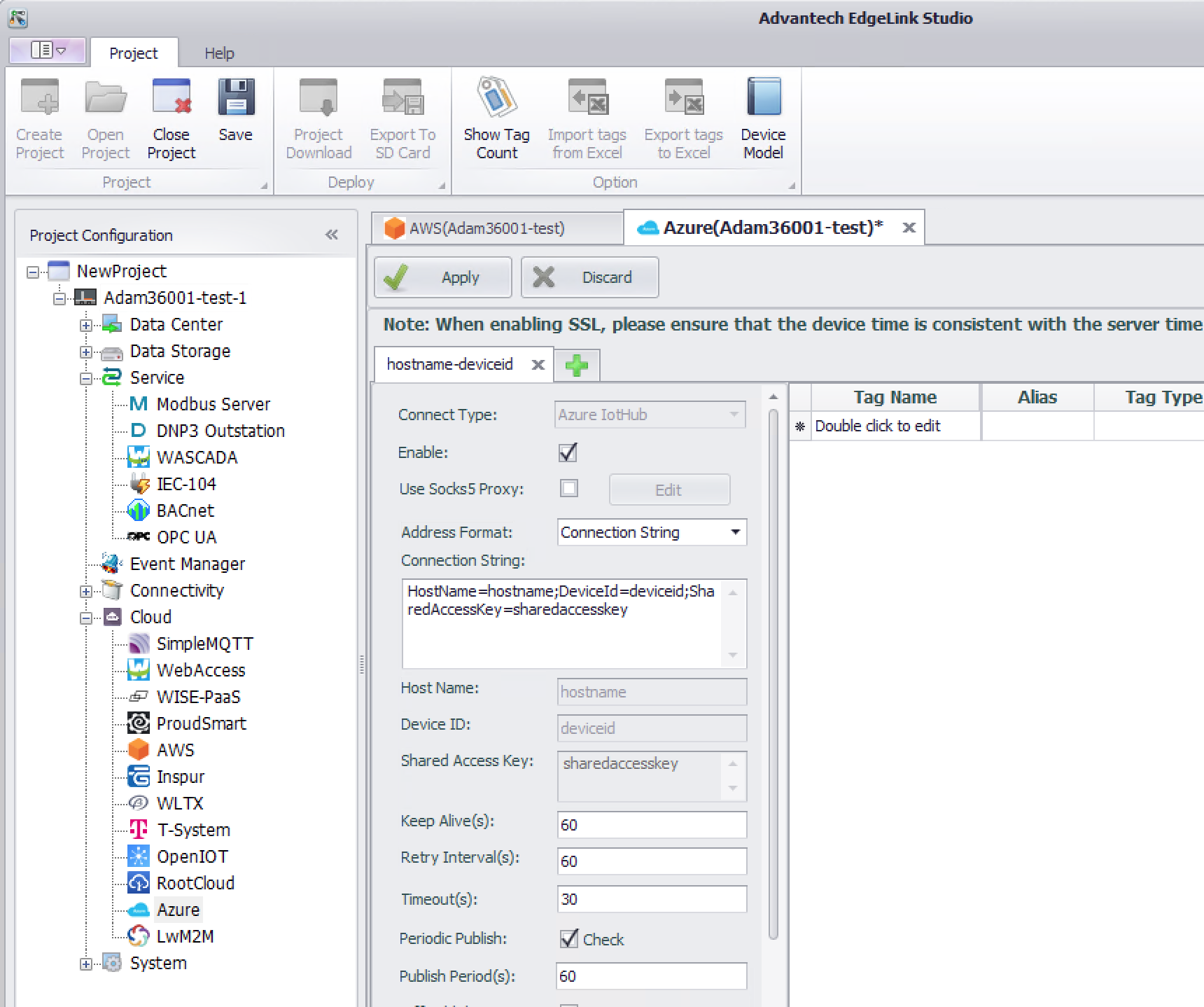

Using the MQTT protocol, you can organize data collection directly to cloud services such as Microsoft Azure IoT Hub, Amazon AWS IoT, etc.

The device is configured in the EdgeLink Studio graphical environment, which allows you to configure the device in data collection mode or in a remote terminal without writing any program code. This allows you to significantly simplify the implementation.

Affordable Cloud Providers at EdgeLink Studio

Programmable logic controller

The ADAM-3600 firmware is based on RT Linux - a special version of the hard real-time operating system. At the same time, the platform is completely open, developers have root access to the system. This allows you to implement any non-standard solutions using system programming languages. Advantech provides an SDK for C / C ++ languages, as well as a development environment and Toolchain for building projects for Linux.

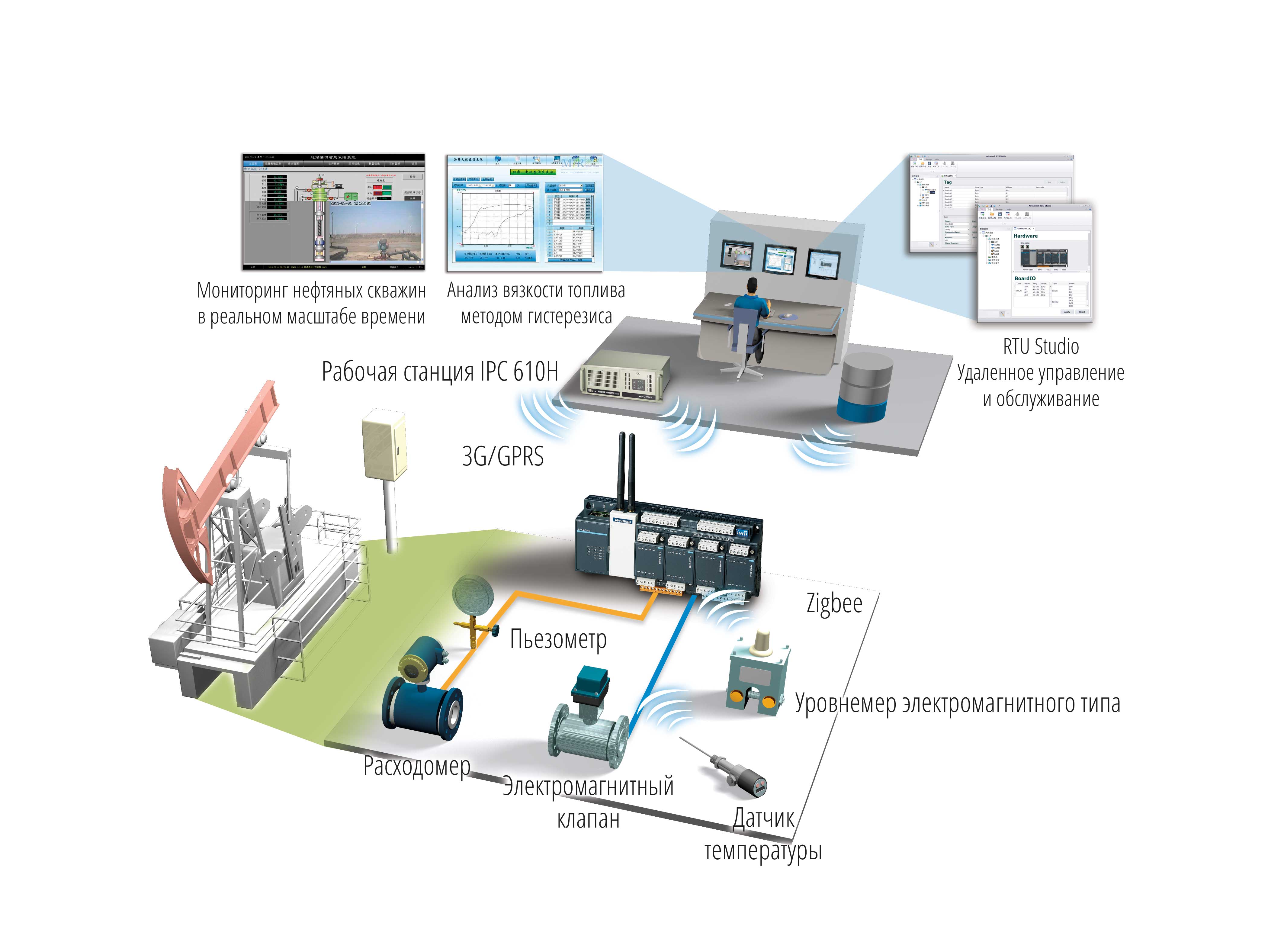

Usage scenario: real-time monitoring of oil wells

On our website, in the training materials section, we publish product usage scenarios www.advantech.ru/resources/. One of the common scenarios for using the ADAM-3600 controller is monitoring and control of drilling and pumping stations. Advantech offers a full range of solutions for building an automatic process control system, in particular, a SCADA system with a web interface - Advantech WebAccess.

Basic tasks of the system:

- Monitoring of oil temperature and “sleeve”, oil pressure, flow rate and other parameters of the pumping unit; as well as reading and saving to the database.

- Connecting sensors via wired (RS-232/485, LAN) and wireless buses (ZigBee)

- Connecting sensors and relays directly to the digital and analog controller interfaces

- Collection of peripheral equipment sensors readings together with statistics on oil production and equipment operation. After the initial processing, the data is sent to the SCADA server.

Oil monitoring system architecture

Conclusion

Thanks to its modular design, the ADAM-3600 controller allows you to select interface ports and wireless protocols based on customer needs, so you can do a large number of tasks with one device. Quick setup features are provided, which makes it easy to install and inventory a large number of devices. The operating temperature range from -40 to 70 ° C makes it possible to use the controller in hard conditions. Support for industry standards and modern IoT protocols allows the ADAM-3600 to integrate into any industrial system.