Real-time oil monitoring with iRTU

Against the backdrop of the rapid development of information technology, computing, management and network communication technologies have gained wide popularity in business and manufacturing. For example, when operating oil and gas fields, it has become possible to use a global remote monitoring system to monitor the effectiveness of oil and gas production, as well as the state of operation of equipment and sensors.

System features

- Monitoring of oil temperature, oil pressure, flow rate and other parameters of the pumping unit; as well as reading and storing indicator information in the database. In addition, Zigbee and other data transfer protocols allow you to connect to wireless sensors in the field (including temperature and pressure sensors).

- Easy to install and maintain. Easy system adjustment for different wellheads.

- Sensors data of the peripheral equipment together with statistics on oil production allow us to evaluate the efficiency of the downhole equipment. After the initial processing, the data is sent to SCADA (top-level software).

- Events have their own timeline, which provides the basis for further analysis and improvement.

- Remote monitoring of system status and updating software features.

System description

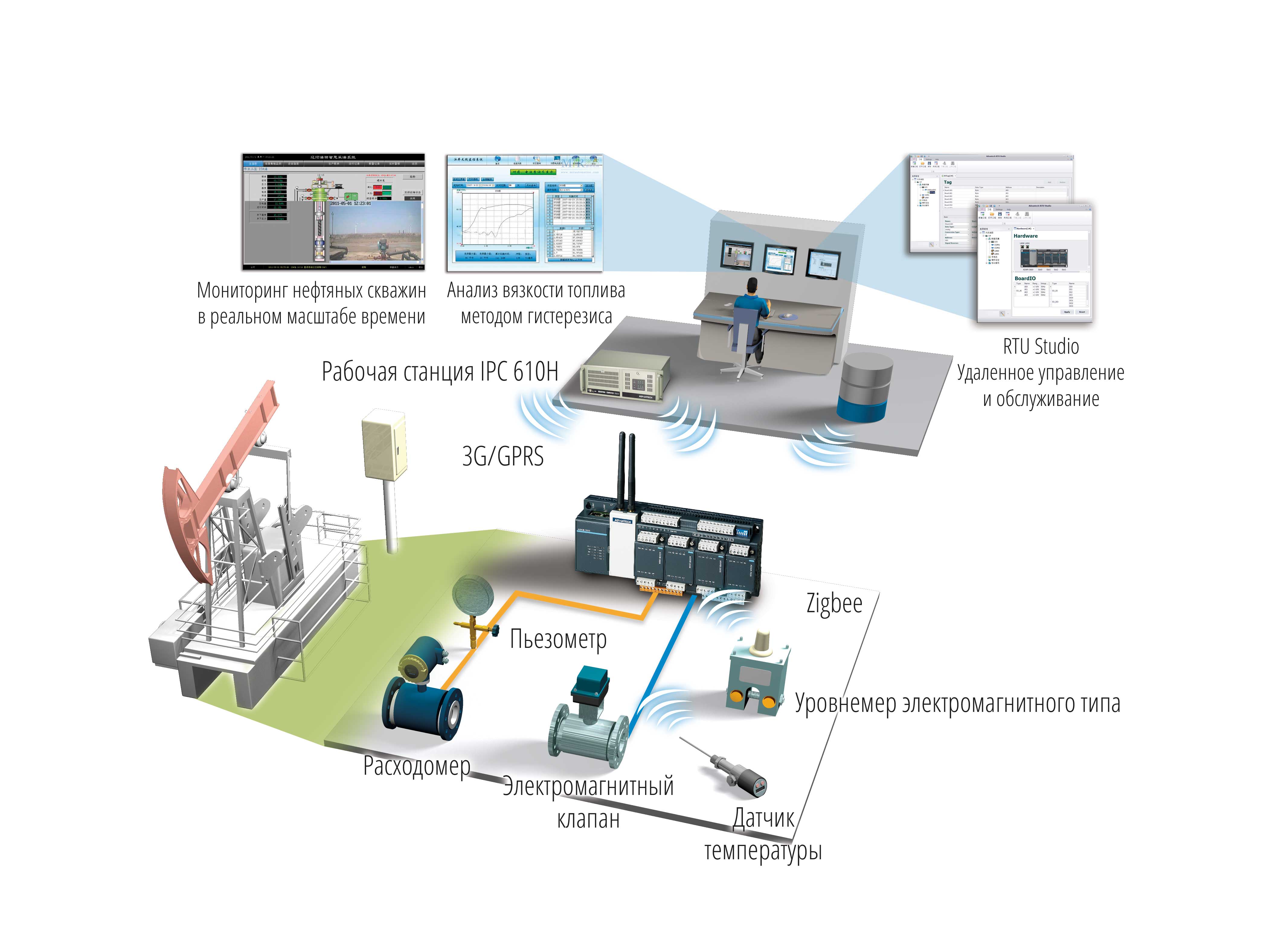

Using the open system architecture of the device, the ADAM-3600 provides two types of wireless communications (3G and Zigbee) to collect wireless sensor data in the field and remotely communicate with the cloud. ADAM - 3600 is specially designed for installation in an automation cabinet: terminal blocks are located on the top and bottom of the device, on the front panel there are signs and indicators that can be used to determine the status and detect malfunctions. Between nodes, four small expansion slots can be installed for various needs. The internal open architecture of the ADAM-3600 is easy to program and maintain, clients can process data in the RTU, as well as remotely analyze large amounts of data. ADAM-3600 includes iRTU Studio software, so you can remotely configure and update the system, which significantly reduces labor and material costs.

Project Composition

- ADAM-3600-C2G: Wireless Intelligent Remote I / O Terminal: 8AI / 8DI / 4DO / 4-Slot Expansion Wireless Intelligent RTU

- Advantech WebAccess: SCADA browser-type system

- IPC 610H: Industrial PC with LED indication on the front panel.

- Peripheral equipment: piezometer, flowmeter, solenoid valve, temperature sensor, electronic level meter, wireless communication equipment.

System architecture