Builds an One-stop LCD Factory Monitoring Solution in 4 Steps

The era of smart factory

Smart factories have entered the manufacturing mainstream. In this environment, intelligent platforms that connect facilities, integrate data with the Internet, and visualize every step in the production process provide a massive competitive edge for producers operating across a wide range of industries. Further actions — analyzing data, adjusting supply chains, and reducing facility failures — can now be efficiently completed using visible data. Technology companies are continually deploying smart systems in their factories.

Being smart is a global trend

Blind spot of traditional management method

In LCD factories, implementing intelligent platforms has become the preferred method for monitoring mask aligners. In the past, data acquisition (DAQ) on mask aligners was done with oscilloscopes during the TFT array process. Electronic testing instruments displayed signal voltages as a two-dimensional plot. The waveform was then analyzed for properties such as amplitude, frequency, and rise time. However, while oscilloscopes processed data, they couldn’t capture and display signals. Processing time became dead time and the immediate management of mask aligners during the manufacturing process wasn’t possible. In addition to the difficulties with immediate monitoring, the high price of oscilloscopes was another essential factor influencing decisions to seek out an alternative approach. A brand new oscilloscope often reached the $1000usd range — rendering it unaffordable for many companies.

Advantech one-stop solution for better system monitoring

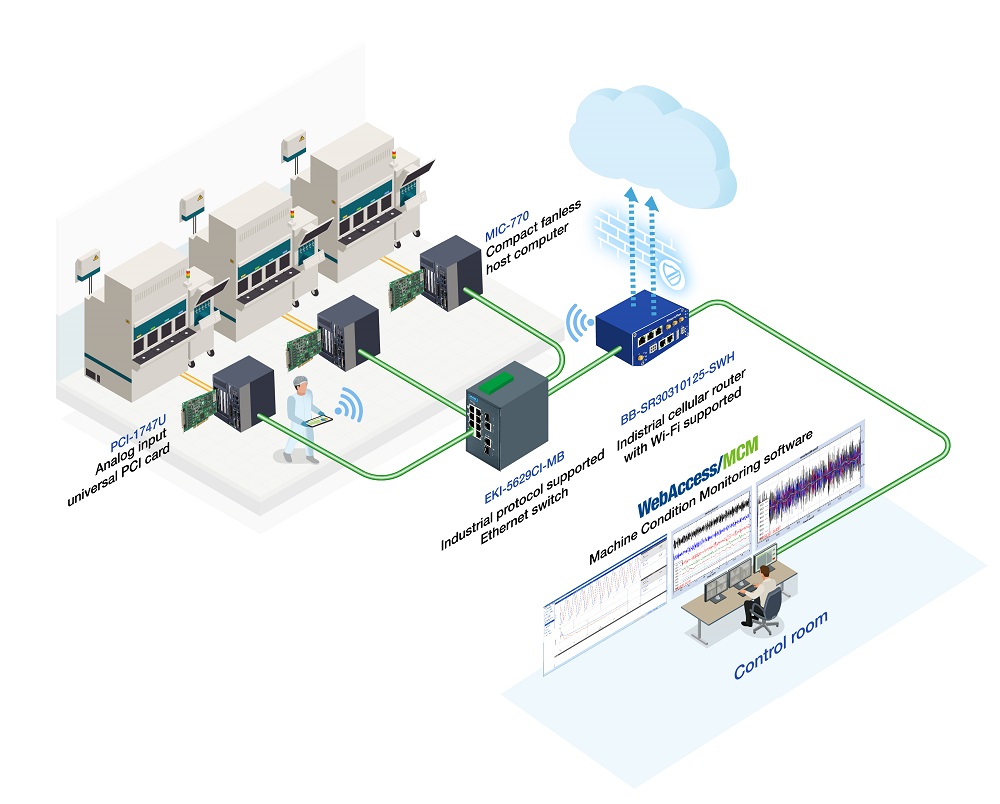

In this case, Advantech provided a one-stop solution with services. By introducing Advantech’s advanced measurement techniques, LCD factories achieved better system monitoring. Each LCD mask aligner was connected with the DAQ system, which then transferred facility data to the online platform. Devices deployed in this system included Industrial Ethernet switches EKI-5629CI-MB for wired network communication, cellular router BB-SR30310125-SWH for wireless data transmission, Intel 8th generation core i processor compact fanless system MIC-770, analog input universal PCI card PCI-1747U, and machine condition monitoring software WebAccess/MCM.

Step 1: Industrial computer and analog input card for data acquisition

To provide a customized system with flexibility, the MIC-770 host computer was equipped with i-Module and flexible I/O interfaces. i-Module, an original flexible expansion module that provides 2~4 expansion slots for the PCIe/PCI interface; while flexible I/O interfaces, located in the front panel for convenient cabling, can support various displays, expansion I/O, and intelligent alarm functions to enable diverse machine automation applications. With the modular-design, MIC-770 let users add expansion cards or I/O corresponding to their own factory facility interface and save time on changing the existent interface design.

While the MIC-770 provided steady data transmission, PCI-1747U — a 64ch, 16bit, 250kS/s high-channel-count analog input card — offered the resolution needed for most data acquisition applications. Advantech also supplied users with high speed DAQ cards to meet their needs.

Step 2: Industrial Ethernet switch for local network communication

Several industrial computers were connected to an industrial Ethernet switch, and the collected data was therefore entering the network communication world. The EKI-5629CI-MB Industrial Ethernet switch supported not only Ethernet communication but also ModbusTCP/IP that allowed for seamless machine data exchange and transmission. Its rugged industrial -40 ~ 75oC duration design guaranteed continuous operation in harsh environment. Supporting network redundancy functionality, the non-stop network communication service was stable and reliable.

Step 3: Industrial cellular router for remote wireless connectivity

As the Ethernet switch was in charge of local network connectivity, the SmartFlex LET/LAN cellular router was there for remote wireless connectivity. Equipped with multi-interface design, the cellular router provided connectivity of I/O, serial and Ethernet devices. When the LCD factory status was delivered to the SmartFlex cellular router, it would be then sent to remote control center in real-time without any network infrastructural or geographical limitation.

Step 4: WebAccess/MCM for central management

As an alternative monitoring system, the host installed WebAccess/MCM offering multiple functions such as sensor signal collection, signal analysis, data management, and alert notification. Depending on different situations and managed targets, customers chose different application modes from MCM. For LCD factories, the Scope Mode presented a suitable alternative monitoring system with functions similar to oscilloscopes — including cursor measurement tools, automatic measurement functions which could be triggered under certain condition such as amplitude and frequency, and immediate display of the spectrogram.

Briefing the success of this project

As intelligent monitoring platforms increasingly enter the mainstream, companies are rushing to implement them into their factories. In LCD production facilities — where oscilloscope cannot capture signals from mask aligners during the processing phase — data is not collected and analyzed instantly. Due to the high price of oscilloscopes, companies are searching for alternative methods to manage mask aligners. To meet customization needs, Advantech provides a one-stop shop for equipment, including the EKI-5629 Ethernet switch, SmartFlex cellular router, MIC 7500 industrial computer, PCI-1747U DAQ cards, and WebAccess/MCM software. With the host offering flexible expansion modules, high-speed DAQ cards, reliably non-stop network transmission and software supporting immediate monitoring systems similar to oscilloscopes, customers will spend less time on facility management while improving production rates by accessing instantly visible data.