Solutions for equipment manufacturers

Introduction

The pharmaceutical industry increasingly relies on intelligent automation to meets safety requirements, improve product quality, and minimize human error and perturbations in the production process.

Chutian Technology Company is one of China’s foremost pharma equipment developers. Based in Hunan Province, Chutian works closely with leading automation experts, including Advantech, in building advanced intelligent automation solutions that meet demand in vertical markets by delivering quality-assured products.

One example of this reciprocal partnership is Chutian’s production of intelligent monitoring and control equipment used on pharma production lines. This equipment integrates Advantech’s high performance industrial controllers and panel PCs for outstanding industrial craftsmanship.

Challenge

The pharma inspection equipment requires the highest level of precision, accuracy, consistency, and stability. The system acquires images and implements data processing and image analyses. Higher computing ability allows for the system to process and analyze more images within a given period of time. To achieve precise, high quality inspection at rapid speed, performance computing power (including graphics processing power) is the most important requirement for industrial computers embedded in the system

Additionally, to withstand operation in hazardous environments and maintain strict hygiene standards, the system must have full IP66-rated ingress protection.

Solution

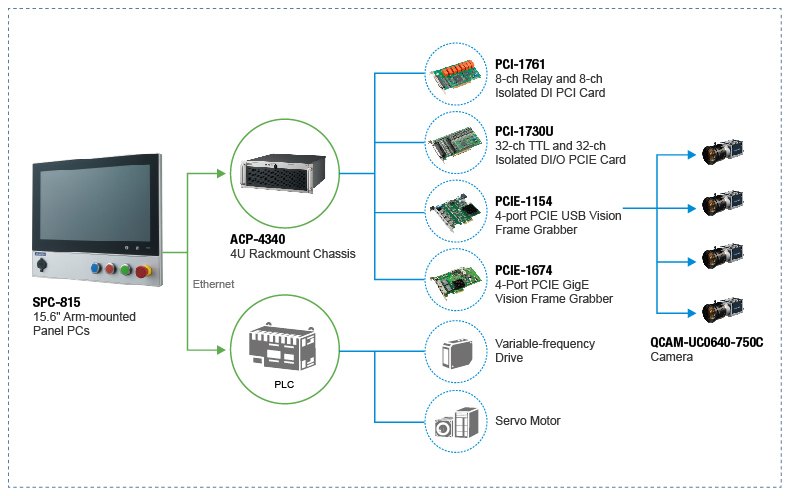

Chutian’s intelligent inspection system for pharma production is based on the following client/server architecture: Advantech’s SPC-815 industrial panel PC functions as a server connected to several ACP-4340 industrial controllers (clients) at various workstations dedicated to defect detection.

The industrial controller at each workstation connects to a PLC via a PCI-based interface to enable automatic motion controls. It connects to camera(s) via a USB card or PoE interface of the PCIe standard to acquire, process, and analyze images and upload the results to the SPC-815W for integrated analysis and storage.

The industrial panel PC not only visualizes and displays processed data, but also executes algorithms provided by the backend computer and delivers feedback to controllers and PLCs. Accordingly, SPC-815 connects and communicates with all parts of the system and facilitates motion and vision control applications required for industrial IoT. Moreover, SPC-815 features all-round IP66-rated ingress protection and supports arm mounting, enabling direct deployment on the machine. This reduces the overall equipment footprint, ensuring easy installation.

Benefit

In the past, medicine inspection was conducted by manual. More than a dozen people were required to perform manual tests, and a two-shift work system was implemented. The daily output of the pharmaceutical factory was 200,000 to 300,000. After adopting Chutian’s pharma inspection equipment, the production line speed is increased, and 5 batches of drugs can be produced per day, the output of each batch of drugs is 150,000, and the daily output of oral liquid is about 700-750 thousand. As productivity increases, workers can adopt a one-shift system. Chutian’s inspection machine help users save labor and time costs while ensuring the quality and safety of medicines.