AI Defect Inspection for Textile

Background Information

Nowadays, the pace of industrial development is increasing and Taiwan’s traditional textile industry wants to catch the global trend for fast fashion. The textile industry like textile manufacturers and fabric mills need to accelerate their upgrade roadmap to get to market faster. In traditional textile industries, design, selection, spinning, weaving, dyeing, and finishing, all consume a lot of resources and time. For example, it takes several days or weeks to manually identify the right types of fabrics and quality materials. However, if there are material defects, it can seriously stall the whole process from pre-production all the way to mass production phases and of course, delivery to the customer.

Thanks to artificial intelligence (AI), manual operations like textile or fabric pattern inspection can be performed by smart AI models. Robotic mechanical arms can perform many routine automated processes in textile manufacturing. When we combine robotic arms with AI capability, textile manufacturing processes can be significantly shortened from weeks to days to hours even. AI can really make a radical difference to the whole textile industry

System Requirements

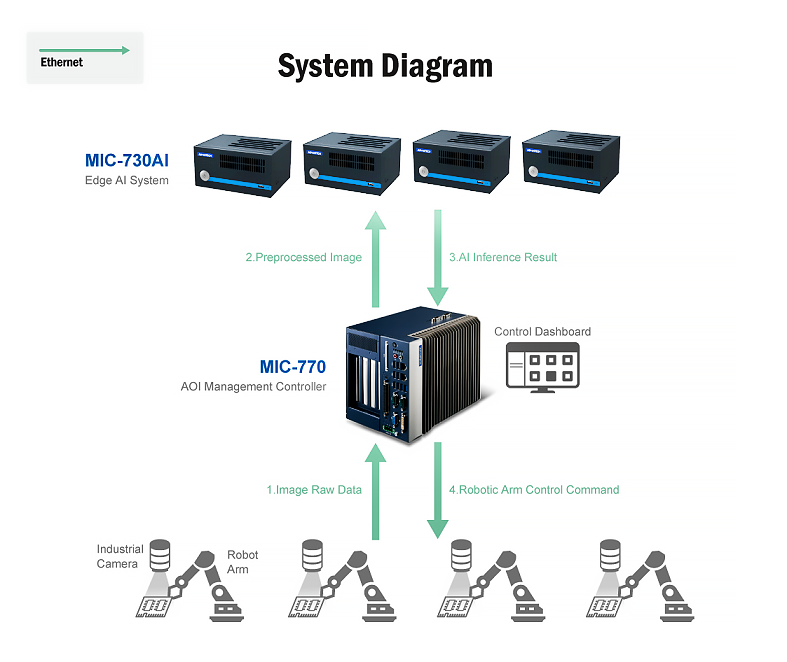

An AI-guided robotic arm solution is powered by distributed computing, which has the scalability and flexibility needed to meet requirements at the edge. A centralized management system takes high speed raw images from all industrial cameras on the production line, and then delivers pre-processed images to edge AI systems for textile defect inspection. These industrial cameras run on the GenICam standard via high throughput gigE Power over Ethernet (PoE).

The management system needs high processing capabilities to perform image pre-processing in parallel, such as contrast adjustment, image calibration, and image segmentation. Then, pre-processed images will be sent to the edge AI system to perform AI inference and return metadata results back to the management system. Once defects are recognized, the management system will control the robotic arms to identify and rectify the defective materials. Since there are a multitude of textiles and materials and many different types of possible defects, corresponding AI models needed to be specified and deployed by the management system.

System Description

The management system played an important role in the distributed computing system and needed powerful computing capability to deal with all the image pre-processing. Image pre-processing makes raw data more compatible for subsequent AI inference. Well-designed pre-processing can not only significantly reduce the edge AI workload but also raises the accuracy of AI inference. MIC-770 supports 8th gen Intel® Core™ i CPUs and has the flexibility to integrate a GigE PoE card via an expansion i-Module. MIC-770 meets all computing requirements as the management system can handle all connected edge AI systems.

AI inference requires high computation and needs a GPU-based solution to accelerate the computation. MIC-730AI is powered by an NVIDIA® Jetson AGX Xavier™ GPU and is employed as the edge AI system. Jetson Xavier's great processing power makes it possible to automatically inspect high-precision textile goods with better speed and accuracy. Textile defect inspections using AI inference technology can efficiently identify the most subtle defects and ensure high quality products. Now, robotic arms automatically controlled by the management system can pick and remove both good and defective products. Due to this distributed AI-guided robotic arm solution, textile manufacturers, and fabric mills can now monitor and control production yields in real time much better

Key Features

- Full range of products from high computing management system to edge AI system

- Distributed AI-guided robotic arm solution with high scalability and flexibility

- Industrial edge AI system empowers AI computing for textile defect inspection

Why Advantech

To meet all edge AI computing in various environments, Advantech provides an AI end-to-end solution and offers a full range of edge computing and AI inference systems, which integrate to perform AI inference solutions. Advantech’s product offering leverages AI computing to support customers. This AI-guided robotic arm for textile defect inspection solution is designed to help textile manufacturers and fabric mills get up to speed with the trends in AI. Advantech’s MIC-770 and MIC-730AI are perfectly adapted to meet all AI computing requirements.

Key Product

| MIC-730AI | MIC-770 |

|

|

| AI Inference System based on NVIDIA® Jetson AGX Xavier™ |

Compact Fanless System with 8th Gen Intel® Core™ i CPU Socket (LGA 1151) |